Brand: Nenglian

Model Number: NL150E

Certificate: CE/ISO

Place of Origin: Hebei,China

Minimum Order Quantity: 1set

Delivery Time: 3-7 work days

Payment Terms: T/T,Western Union

Supply Ability: 100 Sets per Month

Packaging Details: Standard export packaging

● Outlet(mm) :150

● Flow rate :486-1115m3/hr

● Head H(m): 12-51.5

● Speed: 800-1500rpm

● Efficiency:Max65%

● Materials: Impeller A05

● Impeller:5-Vane Closed Type

● Vane Diameter(mm):381

● Power: Max 120Kw

● Color: Depend on customers’ requirements

● NPSH (m):5-8

● Warranty: 1 year Warranty (except wet-end parts)

1. Introduction:

General Introduction:

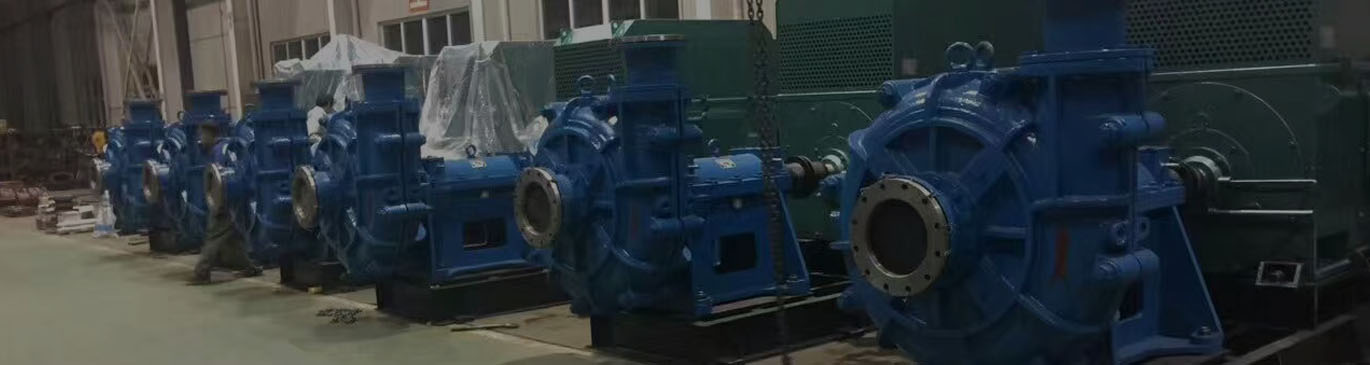

▶Our horizontal slurry pumps are designed for heavy duty applications such as mining, minerals processing, mill discharge, power plants, tailings and other industrial applications, for maximum abrasion, erosion and corrosion resistance.

▶The pumps are in a wide range of sizes, available with both high chrome and ruber wearing parts. Components like impeller and volute come in a range of hard metal types and elastomer to suit the specific application.

▶Different shaft seal types are available to suit every requirement, including gland packing seal, expeller seal and mechanical seal.

▶Our metal lined slurry pumps are designed for heavy duty industrial applications, to handle the most arduous slurries.

▶Wear resistant cast alloys are used for slurry pump liners and impellers where conditions are not suited to rubber, such as with coarse or sharp edged particles, or on duties having high impeller peripheral velocities or high operating temperatures.

▶Designed for rugged duties while offering higher efficiencies, the SL series is a combination of the SH pump’s unique features.

▶The SL series provides the widest range of hydraulics from the 20mm to a 550mm discharge pumps. The 20mm pump is perfect for the laboratory or in demonstration plants.

2.Specifications:

| Pump Model | Outlet (mm) | Allowable Max. Power (kw) | Material | Clear Water Performance | Impeller | ||||||

| Capacity Q | Head H(m) | Speed n(r/min) | Max.Eff. η% | NPSH (m) | No. of Vanes | Vane Dia. (mm) | |||||

| Impeller | m3/h | l/s | |||||||||

| NL/20A | 20 | 7.5 | Metal (A05) | 2.34-10.8 | 0.65-3 | 6-37 | 1400-3000 | 30 | 5 | 152.4 | |

| NL/50B | 50 | 15 | 16.2-76 | 4.5-20 | 9-44 | 1400-2800 | 55 | 190 | |||

| NL/75C | 75 | 30 | 18-151 | 5-42 | 4-45 | 900-2400 | 57 | 2290 | |||

| NL/100D | 100 | 60 | 500-252 | 14-70 | 7-46 | 800-180 | 60 | 2-3.6 | 305 | ||

| NL/150E | 150 | 120 | 1115-486 | 32-135 | 12-51.5 | 800-1500 | 65 | 2-6 | 381 | ||

| NM/200E | 200 | 120 | 666-1440 | 185-400 | 14-60 | 600-1100 | 73 | 4-10 | 549 | ||

| NM/200F | 200 | 260 | 666-1440 | 185-400 | 14-60 | 600-1100 | 73 | 4-10 | 549 | ||

| NL/250E | 250 | 120 | 396-1425 | 110-396 | 8-30 | 500-800 | 77 | 2-10 | 550 | ||

| NL/300S | 300 | 560 | 468-2538 | 130-705 | 8-60 | 400-950 | 79 | 2-10 | 653 | ||

| NL/350S | 350 | 560 | 650-2800 | 180-780 | 10-59 | 400-840 | 81 | 3-10 | 736 | ||

| NL/400ST | 400 | 560 | 720-3312 | 200-920 | 7-51 | 300-700 | 80 | 2-10 | 825 | ||

| NL/450ST | 450 | 560 | 1008-4356 | 280-1210 | 9-48 | 300-600 | 80 | 2-9 | 933 | ||

| NL/550TU | 550 | 1200 | 1980-7920 | 560-2200 | 10-50 | 250-475 | 86 | 4-10 | 1213 | ||

Driven Type:

DC(z): The pump and the engine is directly connetced by a coupling.

Belt-driven Types: The pump and the engine is connetced by pulleys and belts — CV, CR(z), ZV(z).