Specifications:

| SH Series Metal Slurry Pump Specifications |

Pump

Model | S×D

(inch) | Allowable

Max. Power (kw) | Material | Clear Water Performance | Impeller | Pricing |

| Capacity Q | Head

H(m) | Speed

n(r/min) | Max.Eff.

η% | NPSH

(m) | No. of

Vanes | Vane Dia.

(mm) | Weight

(kg) |

| Impeller | m3/h | l/s |

| NZ/25B | 1.5×1 | 15 | Metal

(A05) | 12.6-28.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2-4 | 5 | 152 | 91 |

| NZ/40B | 2×1.5 | 15 | 32.4-72 | 9-20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 184 | 118 |

| NZ/50C | 3×2 | 30 | 39.6-86.4 | 11-24 | 12-64 | 1300-2700 | 55 | 4-6 | 214 | 191 |

| NZ/75C | 4×3 | 30 | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4-6 | 245 | 263 |

| NZ/75D | 4×3 | 60 | 245 | 363 |

| NZ/100D | 6×4 | 60 | 162-360 | 45-100 | 12-56 | 800-1550 | 65 | 5-8 | 365 | 626 |

| NZ/100E | 6×4 | 120 | 365 | 728 |

| NZ/150E | 8×6 | 120 | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 510 | 1473 |

| NZ/150F | 8×6 | 260 | 510 | 1496 |

| NZ/150R | 8×6 | 300 | 510 | 1655 |

| NZ/200F | 10×8 | 260 | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 686 | 3193 |

| NZ/200ST | 10×8 | 560 | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 686 | 3750 |

| NZ/250F | 12×10 | 260 | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 762 | 3760 |

| NZ/250ST | 12×10 | 560 | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 762 | 4318 |

| NZ/300ST | 14×12 | 560 | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3-10 | 965 | 6409 |

| NZ/350TU | 16×14 | 1200 | 1368-3060 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | 1067 | 10000 |

Material: High Chrome Alloy A05

Material Chemical Requirements, Weight%

| Description | Material Name | C | Mn | Si | Ni | Cr | Mo | Cu | P | V | S | Description | Hardness |

| A05 ASTM A532 | Ultrachrome | 2.92 | 0.98 | 0.54 | 0.8 | 27 | ≤0.8 | … | 0.062 | … | 0.051 | 27% Cr Erosion Resistant White Iron | 58-62HRC |

Introduction:

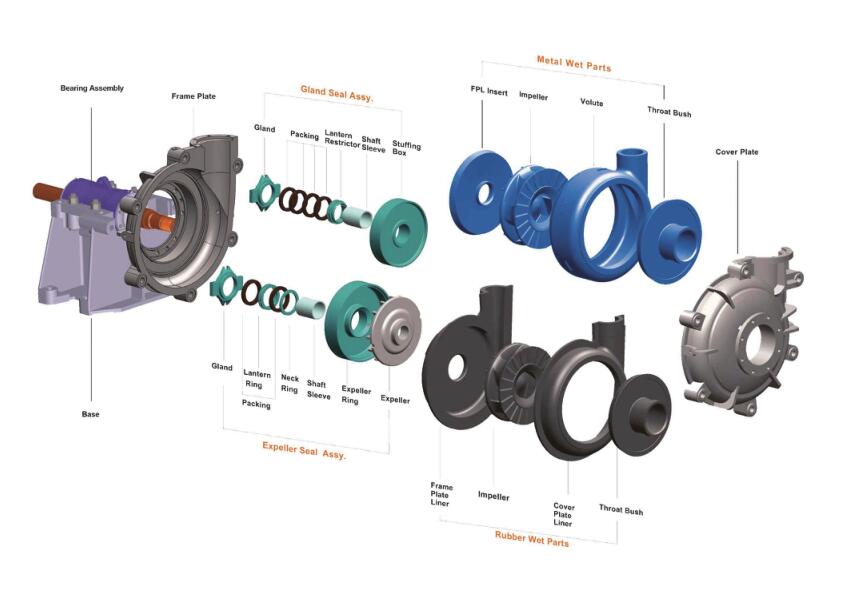

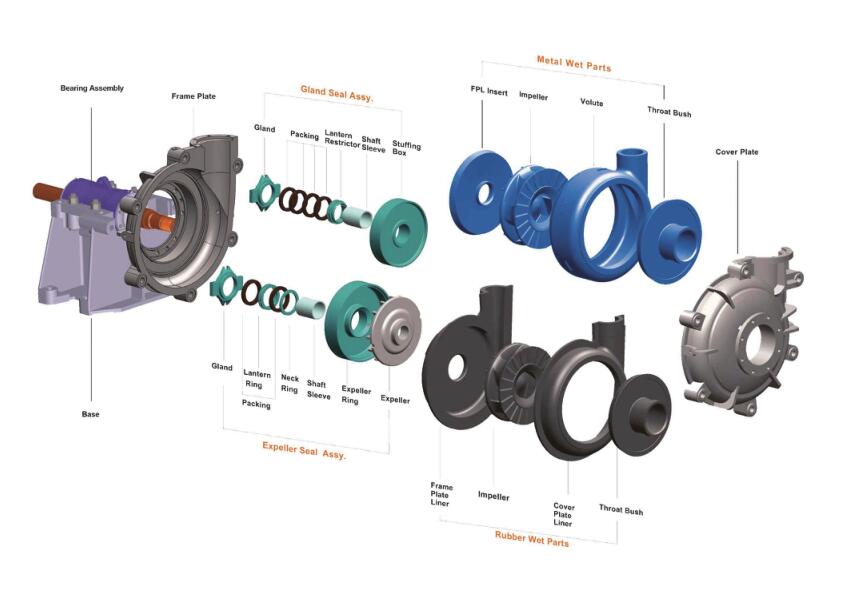

1. Nenglian Slurry pumps are designed with double casing, wet-end parts, and rotary parts. Wet-end parts includes volute, impeller, front and back liner. The rotary parts includes the bearing assembly, which are composed of bearing housing, shaft, bearings etc.

2. This is a heavy duty slurry pump that is extremely durable and easy to maintain. It is highly efficient and corrosion and erosion resistant.

It has a long wear life and is extremely cost efficient. The use of effective liners make this pump easy to maintain.

The pump’s many benefits include the bearing assembly, cover/frame plates, suction cover, liners, the impeller, and it has a one piece base.

3. NZ-250ST is a slurry pump with discharge size 10 inch.

4. NZ-250ST is mostly sold to our customers from Russia, Holland, Italy and other Eastern and Western European countries. Nenglian will always be your reliable partner for quality slurry pumps and pump spare parts.

5. These pumps are characterized by long life, efficient operation and easy maintenance with its low cost.

Pumps are available with either a rubber or a metal lining of abrasive – and corrosion resistant materials. Used bearings for heavy duty, with the increased load on them.

6. Application of Nenglian slurry pumps: mining and processing, mining and metallurgical plants, power plants, cement production enterprises, and diamond-gold mines, technological crushing line, mineral processing, etc.

Construction of SH Slurry Pumps: