- Shifo Industrial Zone, Anguo City, Hebei Province,China

- +8618831216699

sale@nlpumps.com

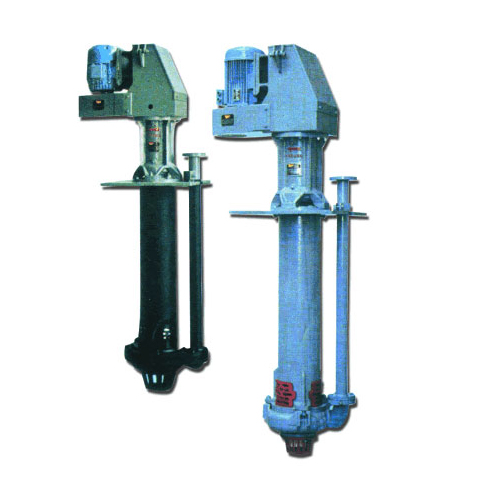

Dimensions and Appearance of a Slurry Pump

Introduction:

A slurry pump is a vital component used in various industries, such as mining, construction, and wastewater treatment, to transport abrasive and viscous fluids mixed with solid particles. Understanding the dimensions and appearance of a slurry pump is crucial for its installation, operation, and maintenance. In this article, we will explore the key aspects of a slurry pump's exterior dimensions, providing a comprehensive overview for those seeking information on this essential equipment.

Overall Dimensions:

A slurry pump typically consists of a pump body, impeller, casing, and various auxiliary components. The overall dimensions of a slurry pump can vary based on its specific design and manufacturer. However, the following are the general measurements one can expect:

Length: The length of a slurry pump can range from 1 to 5 meters (3 to 16 feet), depending on its capacity and application.

Width: The width of a slurry pump typically falls within the range of 0.5 to 2 meters (1.6 to 6.5 feet).

Height: The height of a slurry pump generally varies between 1 to 2.5 meters (3 to 8 feet).

It's important to note that these dimensions are approximate and can be adjusted based on specific requirements.

Weight:

The weight of a slurry pump is a crucial consideration for transportation, installation, and structural support. Depending on the pump's size and materials used in its construction, the weight can vary significantly. Small-scale slurry pumps may weigh around 100 kilograms (220 pounds), while larger industrial pumps can weigh several tons.

Construction Material:

Slurry pumps are manufactured using various materials to ensure durability and resistance to the harsh operating conditions they encounter. The choice of construction material depends on factors such as the type of slurry being pumped, abrasion resistance requirements, and corrosion resistance needs. Common materials used include cast iron, stainless steel, high-chrome alloys, and rubber-lined components.

Exterior Features:

The exterior design of a slurry pump incorporates several features that facilitate its operation and maintenance. These may include:

Inlet and Outlet Ports: Slurry pumps typically have well-defined inlet and outlet ports, allowing for the entry and exit of the slurry mixture. The size and orientation of these ports vary based on the pump's capacity and design.

Access Covers: Slurry pumps are equipped with access covers or inspection hatches to facilitate maintenance activities, such as impeller inspection, cleaning, and replacement.

Mounting Base: Many slurry pumps are designed with a mounting base or feet to provide stability and support during installation.

Paint Finish: To protect the pump from corrosion and enhance its aesthetics, slurry pumps are often coated with a durable paint finish.

Conclusion:

The dimensions and appearance of a slurry pump play a crucial role in its overall performance and installation process. By understanding these aspects, engineers and operators can select the appropriate pump size, ensure proper installation, and effectively maintain the equipment. Moreover, knowing the dimensions aids in determining compatibility with existing piping systems and optimizing space utilization in industrial settings