- Shifo Industrial Zone, Anguo City, Hebei Province,China

- +8618831216699

sale@nlpumps.com

Mud Pump for Water Well Drilling: A Comprehensive Overview

Introduction:

Water well drilling plays a vital role in accessing underground water resources for various purposes such as irrigation, industrial usage, and domestic water supply. One crucial component in the drilling process is the mud pump. In this article, we will delve into the importance of mud pumps in water well drilling, their functionalities, and the key factors to consider when selecting the right mud pump for the job.

Role of Mud Pumps in Water Well Drilling:

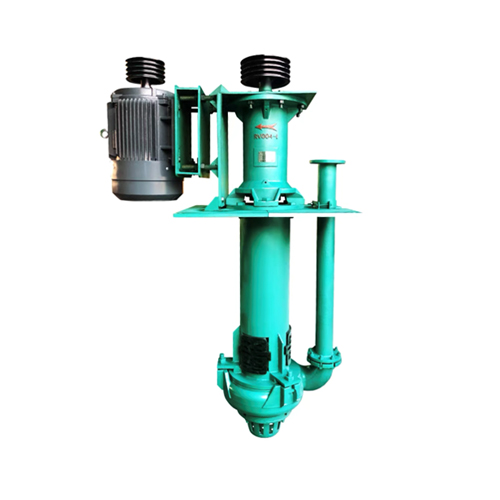

Mud pumps are essential devices used to circulate drilling fluids, commonly referred to as drilling mud, during the drilling operation. These pumps are responsible for creating the necessary hydraulic force to drive the drilling mud down the drill string, through the drill bit, and back to the surface. Mud pumps play a pivotal role in maintaining wellbore stability, lubricating the drill bit, carrying cuttings to the surface, and controlling pressure during drilling.

Functionality of Mud Pumps:

Mud pumps operate on a reciprocating principle, utilizing pistons or plungers to generate high-pressure pulses. The primary functions of mud pumps include:

a. Circulation: Mud pumps ensure continuous circulation of drilling mud, which removes rock cuttings from the wellbore, cools the drill bit, and provides hydrostatic pressure to prevent formation fluids from entering the wellbore.

b. Pressure Control: By adjusting the mud pump's stroke length and speed, operators can regulate the pressure within the wellbore, preventing blowouts and maintaining drilling stability.

c. Lubrication and Cooling: The mud pumped into the wellbore acts as a lubricant for the drill bit and cools down the drilling assembly, reducing the risk of equipment failure due to excessive heat.

Factors to Consider when Selecting a Mud Pump:

Choosing the right mud pump is crucial for successful water well drilling. Several factors should be considered, including:

a. Pump Capacity: The mud pump's capacity should align with the drilling requirements, taking into account the desired flow rate and pressure needed to effectively circulate the drilling mud.

b. Power Source: Mud pumps can be powered by various sources, such as diesel engines or electric motors. The power source should be selected based on factors such as availability, cost, and environmental considerations.

c. Pump Efficiency and Reliability: Reliability is vital to ensure uninterrupted drilling operations. Mud pumps should be reliable, durable, and designed for long-term use in demanding drilling environments.

d. Maintenance and Service: Consider the ease of maintenance, availability of spare parts, and the support provided by the manufacturer or supplier.

Conclusion:

Mud pumps play a critical role in water well drilling, facilitating the circulation of drilling mud, maintaining drilling stability, and ensuring efficient removal of rock cuttings. Selecting the right mud pump involves considering factors such as pump capacity, power source, reliability, and maintenance requirements. By understanding the functionalities and importance of mud pumps, drilling professionals can make informed decisions to enhance the efficiency and success of water well drilling projects.