- Shifo Industrial Zone, Anguo City, Hebei Province,China

- +8618831216699

sale@nlpumps.com

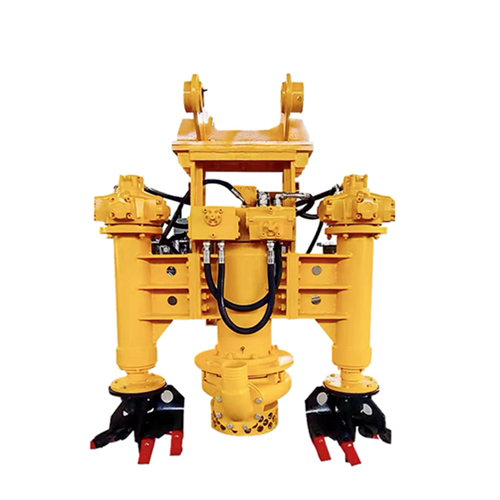

A submersible slurry pump with agitator is a type of pump that is commonly used in industries such as mining, construction, and wastewater treatment. This pump is designed to handle abrasive and corrosive materials that would otherwise damage a standard pump. In this article, we will discuss the features, benefits, and applications of submersible slurry pumps with agitators.

Features of Submersible Slurry Pumps with Agitators

A submersible slurry pump with agitator has several key features that make it an effective tool for handling abrasive and corrosive materials. These features include:

Submersible design: The pump is designed to be fully submerged in the liquid it is pumping, which reduces the risk of leakage and allows it to operate in deeper fluids.

Agitator: The agitator is a device that rotates at high speed and helps to keep solids suspended in the liquid. This prevents the solids from settling and causing blockages.

Heavy-duty construction: Submersible slurry pumps with agitators are constructed from durable materials such as cast iron, stainless steel, or high-chrome alloys. This makes them able to handle the most abrasive and corrosive materials.

High flow rates: The pump is designed to deliver high flow rates of up to 2,000 cubic meters per hour. This allows it to move large volumes of liquid and solids quickly and efficiently.

Easy maintenance: Submersible slurry pumps with agitators are designed for easy maintenance. They have replaceable wear parts and can be disassembled quickly for cleaning and repair.

Benefits of Submersible Slurry Pumps with Agitators

Submersible slurry pumps with agitators offer several benefits over traditional pumps. These benefits include:

Improved efficiency: The agitator helps to keep solids suspended in the liquid, which reduces the risk of blockages and improves overall efficiency.

Reduced maintenance costs: Submersible slurry pumps with agitators have replaceable wear parts, which reduces maintenance costs over the long term.

Increased lifespan: The heavy-duty construction of the pump and its replaceable wear parts mean that it has a longer lifespan than traditional pumps.

Reduced downtime: The pump's high flow rates and ability to handle abrasive and corrosive materials mean that it is less likely to experience downtime due to blockages or damage.

Applications of Submersible Slurry Pumps with Agitators

Submersible slurry pumps with agitators are used in a variety of industries and applications. Some of the most common applications include:

Mining: Submersible slurry pumps with agitators are used to pump abrasive and corrosive materials in the mining industry. They are commonly used in the extraction of minerals such as coal, gold, and copper.

Construction: These pumps are used in construction applications to pump materials such as cement, sand, and sludge. They are commonly used in tunneling and excavation projects.

Wastewater treatment: Submersible slurry pumps with agitators are used in wastewater treatment plants to pump sludge and other solids. They are also used in industrial wastewater treatment applications.

Agriculture: These pumps are used in agriculture to pump manure and other agricultural waste.

Conclusion

Submersible slurry pumps with agitators are a highly effective tool for handling abrasive and corrosive materials. They offer several benefits over traditional pumps, including improved efficiency, reduced maintenance costs, and increased lifespan. They are used in a variety of industries and applications, including mining, construction, and wastewater treatment.